-

Posts

20 -

Joined

-

Last visited

Content Type

Profiles

Forums

Store

Gallery

Events

Local Fish Stores

FAQ

Blogs

Downloads

Posts posted by Buckeye Field Supply

-

-

...any amount of chloramine that makes it through the carbon to the membrane can cause damage to the membrane over time and dramatically shorten the life span of the membrane.

That is true for chlorine, but not necessarily true for chloramine.

You can expect damage in as little as a 1,000 ppm hours from chlorine, but they tested Filmtec membranes up to 300,000 ppm hrs and didn't see damage from chloramine.

The problem is that if you have chloramines, you likely also have some free chlorine.

If you have chloramines, and if you have adequate carbon contact time, and if your pH is over 7.2, you may also see membrane damage and reduced DI life from ammonia. Below 7.2 the ammonia will be present as ammonium and should be largely rejected by the membrane.

Russ

-

What is the water pressure on your gauge?

The suggestion above is a good one - that happens once in a while. The black rubber gasket on the DI cartridge whould be at the top.

Does your unit have a flush valve? If so, is it closed?

Russ

-

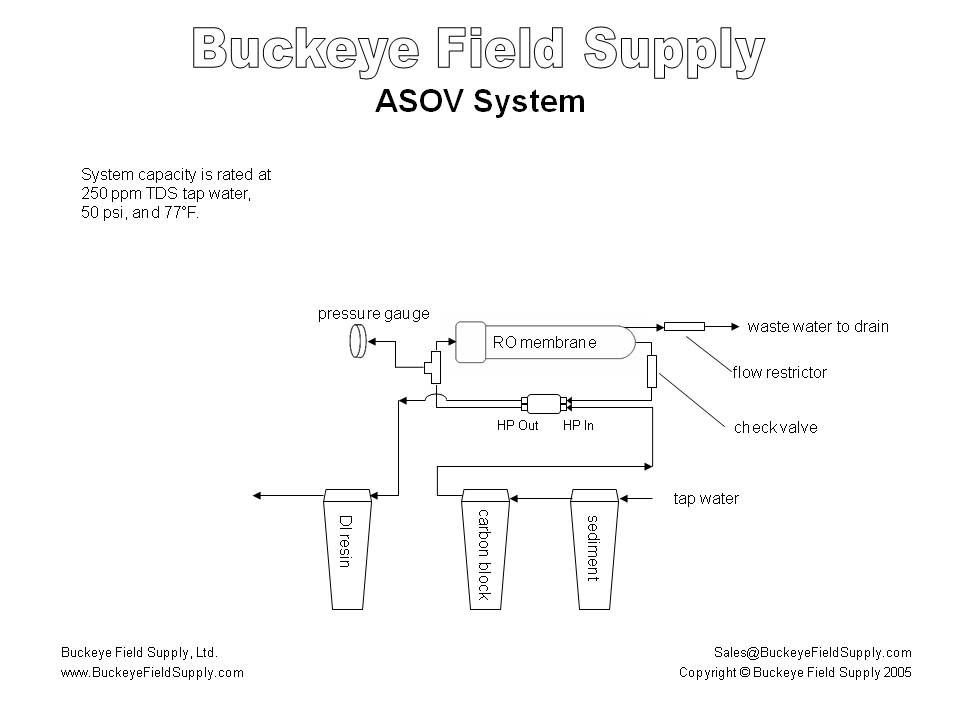

Here's a diagram you can use to check the routing of your tubing:

Russ

-

If the ASOV is working - meaning that it is stopping the flow of waste water when the flow of purified water is stopped, then your check valve is working.

When the ASOV's stop working, it is typically one of 3 things:

1. Float valve leaking

2. Check valve leaking

3. Bad ASOV

The ASOV's "compare" the pressure in the high pressure side of the system to the prssure on the low pressure side of the system. When the low pressure side reaches about 66% of the high pressure side, the ASOV cuts off the high pressure side and stops frow to the RO membrane. The ASOV doesn't add pressure in any way.

Regarding your DI housing - you just have some air trapped in there. With the system running, unscrew the housing a quarter turn and you'll be able to burp the air out of the housing and you'll see the water level start to rise. Just as the water leavel reaches the black oring, cinch the housing tight.

Russ

-

A good rule of thumb is to replace your sediment filter and carbon block after six months. A more precise way to maximize the usable life of these two filters is to use a pressure gauge to identify when pressure reaching the membrane starts to

decline. This is your indication one or both of the filters is beginning to clog.Also be cognizant of the chlorine capacity of the carbon block. A good 0.5 micron carbon block for example will

remove 99% of the chlorine from 20,000 gallons of tap water presented at 1 gpm. Some original equipment suppliers commonly provide carbon cartridges rated at 2,000 to 6,000 gallons. Remember that all the water you process, both waste

water and purified water, go through the carbon block.Regarding your RO membrane and DI resin, use your total dissolved solids (TDS) meter to measure, record, and track the TDS (expressed in parts per million [ppm]) in three places: 1) tap water, 2) after the RO but before the DI, and 3) after the DI.

The TDS in your tap water will likely range from about 50 ppm to upwards of 1000 ppm. Common readings are 100 to 400

ppm. So for sake of discussion, let's say your tap water reads 400 ppm. That means that for every million parts of water, you have 400 parts of dissolved solids. How do we go about getting that TDS reading down to somewhere near zero?

If you do some experimenting with your TDS meter, you'll note that your sediment filter and carbon block (collectively called “prefilters” because the treat the water before it reaches the membrane) do very little to remove dissolved solids. So with your tap water at 400 ppm, you can measure the water at the “in” port on your RO housing and you'll see it is still approximately 400 ppm.The RO membrane is really the workhorse of the system. It removes most of the TDS, some membranes to a greater extent than others. For instance, 100 gpd Filmtec membranes have a rejection rate of 90% (i.e., they reject 90% of the dissolved solids in the feed water). So the purified water coming from your 100 gpd membrane would be about 40 ppm (a 90% reduction). Filmtec 75 gpd (and below) membranes produce purified water (a.k.a. “permeate”) more slowly, but have a higher rejection rate (96 to 98%).

The lifespan of a RO membrane is dependent upon how much water you run through it, and how dirty the water is. Membranes can function well for a year, two years, or more. To test the membrane, measure the TDS in the water coming in to the membrane, and in the purified water (permeate) produced by the membrane. Compare that to the membrane’s advertised rejection rate, and to the same reading you recorded when the membrane was new. Membranes also commonly produce purified water more slowly as their function declines.After the RO membrane, water will flow to your DI housing. DI resin in good condition will reduce the TDS in the RO water down to 0 or 1 ppm. When the DI output starts creeping up from 0 or 1ppm, you know that your resin needs to be replaced. Sometimes people complain that their DI resin didn't last very long. Often the culprit is a malfunctioning RO membrane sending the DI resin “dirty” water. This will exhaust the resin quicker than would otherwise have been the case. Sometimes the problem is poor quality resin – remember that all resins are not created equal.

Additionally, don’t forget to sanitize the entire system at least once per year, and wash and lube your housing o-rings with food-grade silicone grease every filter change.

Russ -

Here are some things to look for in a good system for this hobby:

No more than 4 stages (sediment, carbon, RO, DI) unless you have specific water quality issues you want to address

Standard-sized prefilters, membrane, and DI cartridge

Brand name, high-rejection membrane

Specifications provided for each stage

Pressure gauge after the prefilters and before the membrane

Thermometer

TDS meter (handheld or in-line)

DI bypass

Vertical DI stage

Refillable DI cartridge

Rust-proof bracket

Quick connect fittings

No water from pressurized storage container delivered to DI

Flush valve

Clear housings

High-quality instructions written in clear English

Customer support before, during, and after your purchase

A vendor involved in your hobby

As far as where to buy - we're more than a little biased on that issue so we'll just hush!

Russ

-

The combination of a float valve, (hydraulic) auto shut off valve, and a check valve will keep your reservoir from overflowing. The hydraulic ASOV looks like one of these:

If you go this approach however make sure you manage so that you address the TDS creep issue.

Russ

-

If RODI, change your filters. If flake, switch to frozen rinsed in RODI water.

Remember that your prefilters (the filters before the membrane - typically a sediment filter and carbon block, don't remove tds. A good rule of thumb is to replace your sediment filter and carbon block after six months. A more precise way to maximize the useable life of these two filters is to use a pressure gauge to identify when pressure reaching the membrane starts to decline. This is your indication one or both of the filters is beginning to clog.

Also be cognizant of the chlorine capacity of the carbon block. The Matrikx+1 (“Chlorine Guzzler”) for example will remove 99% of chlorine from 20,000 gallons of tap water presented at 1 gpm. Original equipment suppliers commonly provide carbon cartridges rated at 2,000 to 6,000 gallons.

Regarding your RO membrane and DI resin, use your TDS meter to measure, record, and track the TDS (expressed in parts per million) in three places:

1. Tap water

2. After the RO but before the DI

3. After the DI.

The TDS in your tap water will likely range from about 50 ppm to upwards of 1000 parts per million (ppm). Common readings are 100 to 400 ppm. So for sake of discussion, let's say your tap water reads 400 ppm. That means that for every million parts of water, you have 400 parts of dissolved solids. How do we go about getting that TDS reading down to somewhere near zero?

Russ @ BFS

If you do some experimenting with your TDS meter, you'll note that your sediment filter and carbon block filter (collectively called “prefilters”) do very little to remove dissolved solids. So with your tap water at 400 ppm, you can measure the water at the “in” port on your RO housing and you'll see it is still approximately 400 ppm.

The RO membrane is really the workhorse of the system. It removes most of the TDS, some membranes to a greater extent than others. For instance, 100 gpd Filmtec membranes have a rejection rate of 90% (i.e., they reject 90% of the dissolved solids in feed water). So the purified water coming from your 100 gpd membrane would be about 40 ppm (a 90% reduction). Filmtec 75 gpd (and below) membranes produce less purified water (aka “permeate”), but have a higher rejection rate (96 to 98%). The life span of a RO membrane is dependant upon how much water you run through it, and how dirty the water is. Membranes can function well for a year, two years, or more. To test the membrane, measure the total dissolved solids (TDS) in the water coming in to the membrane, and in the purified water (permeate) produced by the membrane. Compare that to the membrane’s advertised rejection rate, and to the same reading you recorded when the membrane was new. Membranes also commonly produce less water as their function declines.

After the RO membrane, water will flow to your DI housing. DI resin in good condition will reduce the 40 ppm water down to 0 or 1 ppm. When the DI output starts creeping up from 0 or 1 ppm to 3 ppm, 5 ppm, and higher, you know that your resin needs to be replaced. Sometimes people complain that their DI resin didn't last very long. Often the culprit is a malfunctioning RO membrane sending the DI resin “dirty” water. This will exhaust the resin quicker than would otherwise have been the case. Sometimes the problem is poor quality resin – remember that all resins are not created equal!

-

RO is good, RO/DI is better.

I think this is a great answer.

With all the variables associated with starting and running a reef system, using RO and DI is one way to limit the uncertainty involved with the content of the primary media in your tank: water. If the cost of using DI after the RO is a huge factor, my guess is you'll be disillusioned with the hobby in short order because of the overall cost of running a tank.

Russ

-

The beauty of the Filmtec brand membranes is that they are rated at a lower water pressure (50 psi) than the other brands (60 to 65 psi). The factory spec rejection rates of the Filmtec membranes commonly used in this hobby are:

50 gpd: 98%

75 gpd: 98%

100 gpd: 90%

The membranes will perform better at higher pressures, but you don't want to exceed the maximum working pressure of any component in your system, so we typically recommend that folks with a booster pump dial the pump in at no more than 90 psi. Believe it or not, the weak link in the systems (in terms of standing up to high pressure) is often the clear housings.

Russ

-

You don't need to add a second membrane if all you are looking to do is reduce waste water. ANY membrane, or series of two or more membranes can be set up to run at any ratio of waste water to purified water.

The 4:1 ratio we are all familiar with is a recomendation designed to protect the life span of the membrane.

The ratio is controlled by your flow restrictor. Change the restrictor if you want a lower ratio. You don't need to add a second membrane to do this.

Russ @ BFS

-

and which blocks should i use to replace these old ones? i know that the di is a color change, but thats all i know...

Assuming you are on city water, and you don't have chloramines:

a 1 micron sediment filter

a 0.6 micron 20,000 gallon carbon block

and a refillable DI resin cartridge with color changing resin

Russ

-

.

-

Thanks for the support folks.

Filmtec 50 and 75 gpd membranes are spec'ed at 250ppm feedwater at 77 degrees F and 50 psi, and both have a stabilized salt rejection rate of 98%.

The Filmtec 100 gpd is spec'ed at 250 ppm feedwater at 77 degrees F and 50 psi, and has a stabilized salt rejection rate of 90%.

We have a 150 gpd membrane now that is spec'ed at 250 ppm feedwater at 77 degrees F and 60 psi, and has a stabilized salt rejection rate of 98%.

If you don't have conditions that match the factory spec's (few do), we have a calculator on our site that allows to to calculate how much your membrane should produce given your conditions (temperature and pressure).

Russ

-

We're fixing to upgrade our old RO unit w/ a RO/DI. How often does the DI cartridge has to be replaced? Also, does the carbon filter remove chloramine from tap water? One more question, what's the best place to order the unit from? Any information will be well appreciated.

Thanks,

-Cindy-

A good rule of thumb is to replace your sediment filter and carbon block after six months. A more precise way to maximize the useable life of these two filters is to use a pressure gauge to identify when pressure reaching the membrane starts to decline. This is your indication one or both of the filters is beginning to clog.

Also be cognizant of the chlorine capacity of the carbon block. The Matrikx+1 (“Chlorine Guzzler”) for example will remove 99% of chlorine from 20,000 gallons of tap water presented at 1 gpm. Original equipment suppliers commonly provide carbon cartridges rated at 2,000 to 6,000 gallons.

Regarding your RO membrane and DI resin, use your TDS meter to measure, record, and track the TDS (expressed in parts per million) in three places:

1. Tap water

2. After the RO but before the DI

3. After the DI.

The TDS in your tap water will likely range from about 50 ppm to upwards of 1000 parts per million (ppm). Common readings are 100 to 400 ppm. So for sake of discussion, let's say your tap water reads 400 ppm. That means that for every million parts of water, you have 400 parts of dissolved solids. How do we go about getting that TDS reading down to somewhere near zero?

If you do some experimenting with your TDS meter, you'll note that your sediment filter and carbon block filter (collectively called prefilters) do very little to remove dissolved solids. So with your tap water at 400 ppm, you can measure the water at the “in” port on your RO housing and you'll see its still approximately 400 ppm.

The RO membrane is really the workhorse of the system. It removes most of the TDS, some membranes to a greater extent than others. For instance, 100 gpd Filmtec membranes have a rejection rate of 90% (i.e., they reject 90% of the dissolved solids in feed water). So the purified water coming from your 100 gpd membrane would be about 40 ppm (a 90% reduction). Filmtec 75 gpd (and below) membranes produce less purified water (aka “permeate”), but have a higher rejection rate (96 to 98%). The life span of a RO membrane is dependant upon how much water you run through it, and how dirty the water is. Membranes can function well for a year, two years, or more. To test the membrane, measure the total dissolved solids (TDS) in the water coming in to the membrane, and in the purified water (permeate) produced by the membrane. Compare that to the membrane’s advertised rejection rate, and to the same reading you recorded when the membrane was new. Membranes also commonly produce less water as their function declines.

After the RO membrane, water will flow to your DI housing. DI resin in good condition will reduce the 40 ppm water down to 0 or 1 ppm. When the DI output starts creeping up from 0 or 1 ppm to 3 ppm, 5 ppm, and higher, you know that your resin needs to be replaced. Sometimes people complain that their DI resin didn't last very long. Often the culprit is a malfunctioning RO membrane sending the DI resin “dirty” water. This will exhaust the resin quicker then would otherwise have been the case. Sometimes the problem is poor quality resin – remember that all resins are not created equal!

RE Chloramines:

Carbon does not remove chloramines - but given adequate contact time, the carbon with split the chloramine into chloine and ammonia. The carbon will take care of the chlorine, and ammonia needs the be handled by later stages in the system.

Re where to order a system from... Well, we are a little biased on that topic!

Russ @ BFS

-

That looks like it! My current one is plastic but I'm assuming a metal one would be OK. How does it attach to the RO hose (glue, etc?), and can I get these at Home Depot?

The 1/4" plastic tubing for your RO system simply slips into the quick connect fitting - stick it in and you're done.

You'll not find these at a hardware store. We've pm'ed you a source.

Russ

-

I need to repair/replace the end (female adaptor?)of the hose that connects to my water hose. It's very slightly damaged, but doesn't screw on correctly (it pops off of the hose about every 10 min) and leaks badly right behind the end (where the screw on end is connected to the rest of the RO hose). If I don't hit a certain pressure no water comes out of the blue hose, or it drips slowly. But at that same pressure the RO hose pops off of the water hose and leaks out about 10 times more water than I'm collecting.

Can the hose end be successfully replaced?

If you are talking about a fitting that takes you from garden hose threads to a quick connect for 1/4" tubing, those are called "hose bib adapters" and would take you all of about 30 seconds to replace - very easy.

-

Welcome to the board and club!

Can you let me know how hard it is to "recharge" di resign?

BTW your site has helped me through several RO/DI issues.

Headless Donkey - now THAT'S a username!

How hard? If you are comfortable working around strong acids and bases, and you use separate bed resins, it's not that difficult. Unless you have a fair amount of resin to recharge however, I would think it more trouble than it's worth, given the price of refillable DI cartridges and resin refills.

Russ

-

Hi folks - We just discovered your board and this is our first post. We'll keep our eyes open for people needing help with RO and RODI / water purification issues.

Russ @ BFS

Does anyone's RODI Reservoir Stink?

in Reef Keeping

Posted

I'm certain everyone is sanitizing their RODI system at least once a year, right??